Why Aluminium Pressings Excel in Aerospace Fixtures

This is a subtitle for your new post

In the aerospace industry, precision, strength, and reliability are essential when selecting materials for aircraft components. Aluminium pressings, produced through techniques such as deep-drawn presswork, have emerged as one of the most favoured options for manufacturers in the aerospace sector. Due to their unique combination of properties, including lightweight construction, corrosion resistance, and exceptional strength-to-weight ratio, aluminium pressings are indispensable for enhancing the performance and safety of aircraft.

At Cotmor Tool and Presswork, we specialise in producing high-quality aluminium pressings, including deep drawn presswork and precision presswork, for a variety of industries, with aerospace being a key sector. In this guide, we explore why aluminium pressings are so well-suited for aerospace fixtures, their benefits, and how precision presswork contributes to the production of complex components essential for aircraft assemblies.

What Are Aluminium Pressings?

Aluminium pressings are components shaped from sheets of aluminium using precision stamping or presswork techniques. Through deep drawn presswork, aluminium is shaped into parts with greater depth than width, which is ideal for creating intricate, repeatable designs. The versatility of aluminium makes it a prime choice for producing a wide range of aerospace components, from structural parts to fixtures and fittings.

The Advantages of Aluminium Pressings in Aerospace Applications

Aluminium offers several distinct advantages in aerospace applications, making it the material of choice for many manufacturers. Here are the primary benefits:

1. Lightweight Properties

One of the main benefits of aluminium pressings in the aerospace sector is their lightweight nature. The aerospace industry demands materials that are light enough to reduce overall weight without compromising on strength. Lighter aircraft lead to less fuel consumption, making them more energy-efficient and cost-effective to operate. The strength-to-weight ratio of aluminium is unparalleled, making it ideal for applications where both strength and weight reduction are critical.

2. Corrosion Resistance

Aluminium is naturally resistant to corrosion, an essential property for parts used in the aerospace industry. Aircraft components are constantly exposed to the elements, including moisture and varying temperatures, and are susceptible to corrosion over time. Aluminium’s resistance to corrosion helps increase the durability and longevity of aircraft fixtures, making it an ideal material for long-term performance in the harshest conditions.

3. Strength-to-Weight Ratio

Aluminium alloys offer a perfect balance between strength and weight, which is a vital factor in aerospace design. Aircraft components made from aluminium pressings retain high tensile strength while being lightweight, a combination that is essential for maintaining the structural integrity of aircraft. This ratio ensures the durability of the components without adding unnecessary weight that could compromise the aircraft’s fuel efficiency and performance.

4. Recyclability

Aluminium is 100% recyclable without losing any of its properties. In an era where sustainability is crucial, this makes aluminium pressings an environmentally friendly choice. The aerospace industry is increasingly focused on reducing waste and lowering carbon footprints, and using recyclable materials like aluminium aligns with these sustainability goals.

Deep Drawn Presswork: The Ideal Technique for Aerospace Components

Deep drawn presswork is an essential process in the production of aluminium pressings for aerospace applications. This method involves drawing a flat sheet of material, in this case, aluminium, through a die to form a deeper, hollow shape. The process allows manufacturers to produce components with complex geometries that can be used in a variety of aerospace fixtures, from fuselage parts to structural brackets.

At Cotmor, we utilise our advanced 400-tonne press capacity to create deep-drawn aluminium pressings that meet the precise requirements of the aerospace industry. Deep drawn aluminium parts offer:

● Repeatability: Deep-drawn components can be made with high precision, ensuring that each part produced meets exact specifications. This repeatability is crucial in aerospace manufacturing, where consistent quality and performance are non-negotiable.

● Complexity: The deep-drawn process allows for the production of components with intricate shapes, perfect for aerospace applications where space constraints and structural integrity are key concerns.

● Durability: Deep-drawn aluminium pressings offer superior strength and resistance to fatigue, ensuring that components remain robust under the stress and pressure of high-performance environments.

Precision Presswork in Aerospace Fixtures

The aerospace industry requires components that are not only lightweight and strong but also highly precise. Precision presswork plays a significant role in achieving the tight tolerances and exact specifications needed for aerospace fixtures. At Cotmor, our team is skilled in delivering precision presswork that ensures each component is made with absolute accuracy.

We use state-of-the-art equipment and advanced tooling to create parts that meet the strictest industry standards. Our experienced engineers take every detail into account, from the materials used to the production methods, ensuring that every aluminium pressing we produce is suitable for aerospace applications. This level of precision is vital for the intricate assemblies found in modern aircraft, where even the smallest error can have significant consequences.

The Importance of Quality Control in Aerospace Applications

In aerospace manufacturing, quality control is paramount. Every component must be thoroughly tested to ensure that it meets the necessary safety standards and specifications. The production of aluminium pressings for aircraft is no exception. At Cotmor, we conduct rigorous quality control checks throughout the manufacturing process to guarantee that every part we produce meets or exceeds industry requirements.

Our quality control process includes:

● Inspection of Materials: Before production begins, we thoroughly inspect the aluminium materials to ensure they meet the required standards for strength, durability, and corrosion resistance.

● Testing of Components: After the presswork is complete, each component undergoes a series of tests to ensure it meets the required specifications for size, shape, and strength.

● Final Inspection: We conduct a final inspection to verify that all parts are free from defects and meet the exact requirements of our aerospace clients.

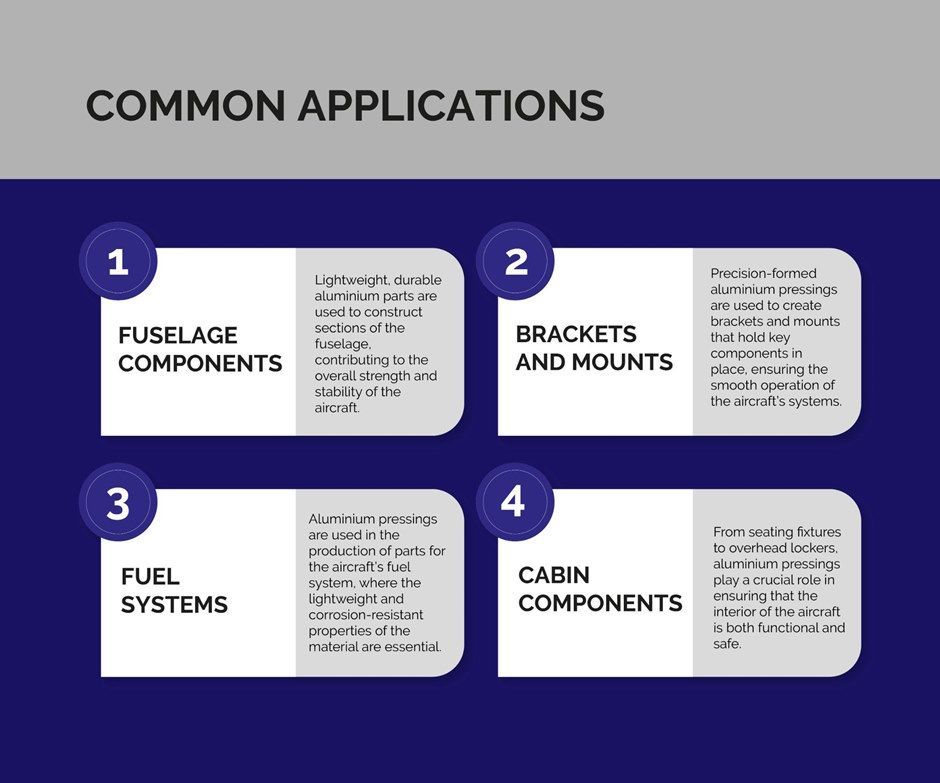

Applications of Aluminium Pressings in Aerospace

Aluminium pressings are used in a wide range of aerospace applications, from structural parts to components that support other systems within the aircraft.

Choose Cotmor for Your Aluminium Pressing Needs

At Cotmor Tool and Presswork, we pride ourselves on providing high-quality aluminium pressings for the aerospace sector. With over 60 years of experience in precision presswork and deep drawn presswork, we are well-equipped to handle the complex requirements of aerospace manufacturers. Our dedication to quality, precision, and customer satisfaction makes us a trusted partner for aerospace fixtures.

We’re ready to support you with high-quality aluminium pressings for your aerospace applications. With decades of experience in presswork, we have the expertise to provide you with the best solutions for your needs.

Contact us today for more information or request a quote for your next project. We look forward to working with you!