Is Metal Pressing the Right Solution for Your Project? Key Considerations

Manufacturers face a crucial decision when choosing the most effective way to produce their parts and components: which process offers the right balance of cost, efficiency, and quality? Among the many techniques available, metal pressing (also known as stamping) remains one of the most widely used thanks to its ability to deliver consistent, high-volume results. But is it always the right choice for your project?

This article explores the advantages of metal pressing services, the situations where it works best, and the scenarios where alternatives such as fabrication or machining may be more suitable. By the end, you should have a clearer idea of whether metal pressing and stamping is the right solution for your requirements. To learn more, keep on reading our blog.

What Is Metal Pressing?

At its core, metal pressing is a manufacturing process that uses specialised machines and presswork tools to shape sheet metal into precise forms. This is typically achieved by feeding flat sheets of metal into a press, where force is applied to cut, bend, punch, or emboss the material into the desired shape.

These processes can be combined within a single production run, enabling manufacturers to produce complex components at speed. Effective metal pressing design is crucial at this stage, as it ensures that the part can be formed efficiently and consistently.

The technique is extremely versatile. Common types of metal pressing and stamping include:

● Blanking – cutting out a flat shape from sheet metal.

● Bending – forming sheet metal at an angle.

● Punching – creating holes or cut-outs.

● Embossing – raising or recessing sections of the material for texture or function.

The Key Advantages of Metal Pressing

There are good reasons why so many industries, from automotive to aerospace and consumer electronics, rely on metal pressing services. Some of the main benefits include:

Cost-Efficiency for High Volumes

One of the strongest arguments for metal pressing and stamping is its economy of scale. While the initial setup, particularly the creation of presswork tools, can be costly, the per-unit price decreases dramatically when producing thousands or even millions of identical parts. For projects that demand volume, pressing offers unbeatable value.

Repeatability and Precision

Modern presses are designed to deliver the same output consistently, run after run. This repeatability ensures that every component meets tight tolerances. For industries such as automotive manufacturing, where precision and safety are non-negotiable, metal pressing services provide the reliability needed.

Design Flexibility

With the right metal pressing design, manufacturers can create highly detailed and complex parts. Shapes that might be time-consuming or expensive to produce via machining can often be pressed quickly and with minimal waste.

Speed and Scalability

Presses can run at high speeds, producing hundreds of components per minute. This rapid throughput makes pressing the go-to choice for manufacturers under pressure to deliver at scale.

Material Efficiency

Unlike certain fabrication techniques that remove material, metal pressing and stamping tends to minimise waste. By optimising the design and cutting process, manufacturers can make the most of each sheet of metal.

Key Considerations Before Choosing Metal Pressing

Despite its many strengths, metal pressing services are not suitable for every project. Before committing to this approach, it’s worth weighing the following considerations:

Project Scale

Metal pressing is most economical for medium to large production runs. If your project only requires a few dozen parts, the upfront tooling costs may outweigh the benefits. In contrast, fabrication or machining could prove more cost-effective for short runs.

Tooling Investment

The creation of presswork tools is often the largest expense in the pressing process. These tools are custom-built for each project and can take weeks to design and manufacture. If you anticipate frequent design changes, the investment may be difficult to justify.

Design Requirements

Not every part is suited to metal pressing design. The process works best for components that can be formed from sheet metal. Very thick sections, deep cavities, or unusual geometries may require machining or other methods instead.

Lead Times

While pressing excels at high-speed production once running, the initial setup can take longer than other methods due to toolmaking and design testing. If you need parts urgently, machining or laser cutting may provide a faster turnaround.

Material Compatibility

Metal pressing and stamping can be applied to many materials, from aluminium and steel to brass and copper. However, some specialised alloys or thicker materials may pose challenges. It’s important to confirm with your supplier that the chosen material suits the process.

When Alternatives May Be Better

Sometimes, even with its strengths, pressing isn’t the best solution. The choice between metal pressing services and alternatives depends on balancing volume, cost, and flexibility. Alternatives such as fabrication, machining, or even additive manufacturing (3D printing) might better suit your project.

● Low Volume or Prototyping: For small production runs, fabrication or CNC machining may be more cost-effective since they don’t require dedicated presswork tools.

● Complex Customisation: Highly intricate parts with fine details may be easier to achieve with machining or laser cutting.

● Frequent Design Changes: If your project involves ongoing design iterations, the cost and time of updating pressing tools may be prohibitive.

● Rapid Turnaround Needs: Pressing requires setup time. In contrast, machining or fabrication may deliver parts more quickly for urgent orders.

The Role of Design and Presswork Tools

The success of any metal pressing and stamping project hinges on design. A carefully thought-out metal pressing design not only ensures part accuracy but also minimises waste, reduces tool wear, and speeds up production.

Presswork Tools

Presswork tools are at the heart of the process. Each tool is tailored to a specific design, dictating how the sheet metal will be formed. Because of this, the quality and durability of the tool directly affect production efficiency and component quality.

Collaboration is Key

Experienced metal pressing services providers often work closely with clients at the design stage. By involving toolmakers and engineers early, potential issues can be identified and resolved before tooling is finalised. This collaboration helps reduce costly redesigns and ensures parts are optimised for pressing.

Long-Term Value

While tooling represents a significant investment, high-quality tools can produce millions of parts before needing replacement. This durability is one of the main reasons pressing remains cost-effective for large projects.

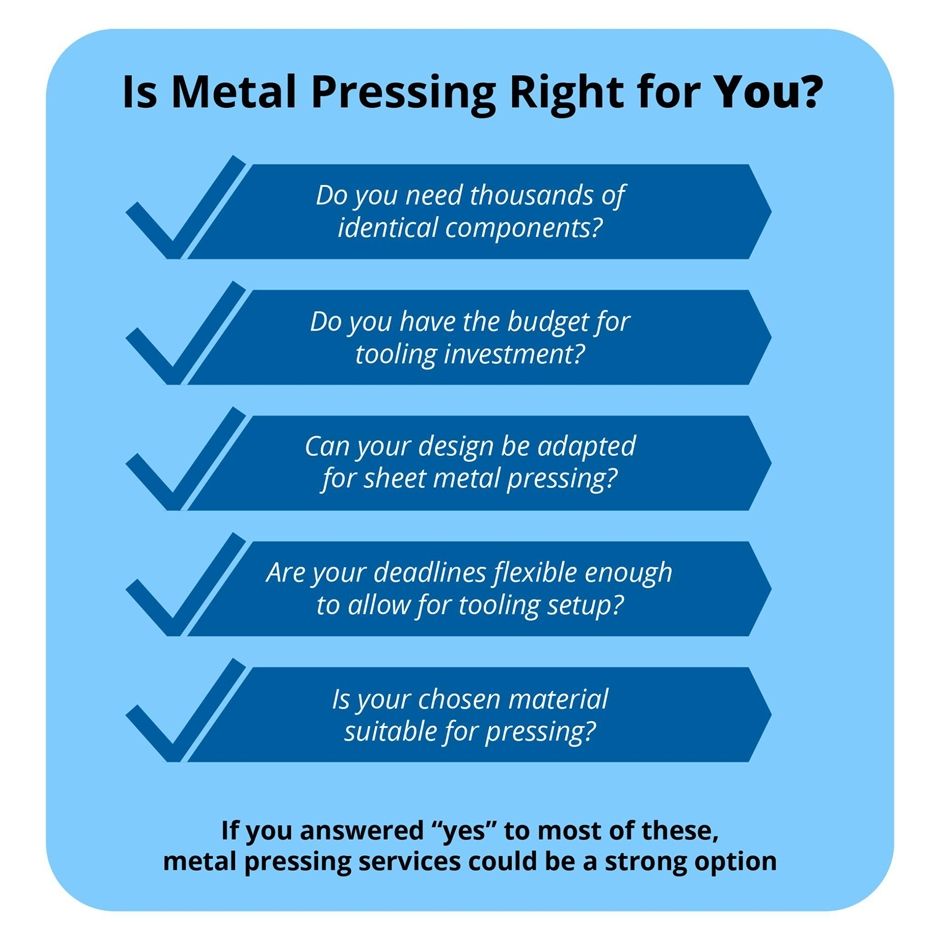

Making the Decision: Is Metal Pressing Right for You?

So, how do you know if metal pressing services are right for your project?

Choose metal pressing and stamping if you need high-volume production, consistent quality, and long-term cost efficiency. Consider alternatives such as machining or fabrication if you require small runs, rapid prototyping, or complex customisation. Remember, the decision should be made in consultation with an experienced provider who can assess your requirements and guide you through the possibilities.

Cotmor Tool and Presswork

Metal pressing is one of the most efficient, reliable, and scalable manufacturing methods available. With benefits such as cost efficiency, repeatability, and speed, it is often the best solution for projects requiring thousands of identical parts. However, it isn’t always the right fit, projects that demand flexibility, quick turnaround, or intricate customisation may be better served by alternatives.

By considering your project’s scale, budget, design, and material requirements, you can determine whether metal pressing services are the right choice. And with the right partner, you’ll benefit from not only advanced presswork tools but also expert guidance at the design stage to maximise success. If you’re exploring options for your next project, get in touch with our team today.