MIG Welding and Spot Welding Explained: A Practical Guide

In metal fabrication and manufacturing, welding plays a vital role in creating strong, reliable joints that support both structural integrity and long-term performance. Two of the most widely used welding techniques across automotive, manufacturing and construction sectors are MIG welding and spot welding. Each process offers distinct advantages depending on material type, thickness and the intended use of the finished metal assemblies.

This combined guide explores how MIG welding and spot welding work, where each method is best applied, and how they contribute to efficient, high-quality metal fabrication.

Understanding MIG Welding

MIG welding, also known as Metal Inert Gas welding, is a process that uses a constant voltage power supply to generate an electric arc between a continuously fed wire electrode and the base metal. As the arc forms, both the filler wire and the parent metal melt and fuse together to create a strong joint.

To protect the molten weld pool from contamination by oxygen or nitrogen in the air, a shielding gas is released through the welding torch. This is typically argon or a blended gas containing elements such as helium, carbon dioxide or oxygen, depending on the material being welded.

MIG welding is widely used because it is highly versatile and well-suited to automation. It can be applied to a broad range of metals, including steel, stainless steel and aluminium, and works effectively across different thicknesses. These qualities make MIG welding particularly suitable for larger or more complex metal assemblies where strength and consistency are critical.

The MIG Welding Process in Practice

Achieving high-quality MIG welds relies on controlling several key factors during the welding process. Correct torch positioning and angle are essential to ensure smooth weld formation and minimise defects such as spatter or poor penetration. Welding speed also plays a significant role, as moving too quickly or too slowly can affect bead shape and joint strength.

Different metal transfer modes can be used during MIG welding, depending on the application. These include short-circuit transfer for thinner materials, spray transfer for thicker sections requiring deeper penetration, and pulsed transfer for controlled heat input. Selecting the appropriate mode helps achieve clean, consistent welds while reducing distortion and rework.

What Is Spot Welding?

Spot welding is a form of resistance welding that joins metal sheets using heat generated by electrical resistance and applied pressure. The process involves clamping metal sheets between two copper alloy electrodes. When an electrical current passes through the electrodes, the metal heats up at the contact point and melts. Once the current stops, pressure remains in place while the molten metal solidifies, forming a weld nugget.

Unlike MIG welding, spot welding does not require filler wire or shielding gas, making it a fast and economical option for certain applications. It is particularly effective for joining thin sheet metals where speed and repeatability are priorities.

Spot Welding in Manufacturing and Automotive Applications

Spot welding is commonly used in high-volume manufacturing environments due to its speed and efficiency. In the automotive industry, it is a primary joining method for assembling vehicle body panels and structural elements made from thin steel sheets. The process allows manufacturers to produce consistent joints rapidly, making it ideal for automated production lines.

Beyond automotive manufacturing, spot welding is widely used in general manufacturing, construction equipment production and the fabrication of appliances, electronics and metal furniture. Its ability to create uniform joints with minimal distortion makes it well-suited to components that require little to no post-weld finishing.

Comparing MIG Welding and Spot Welding

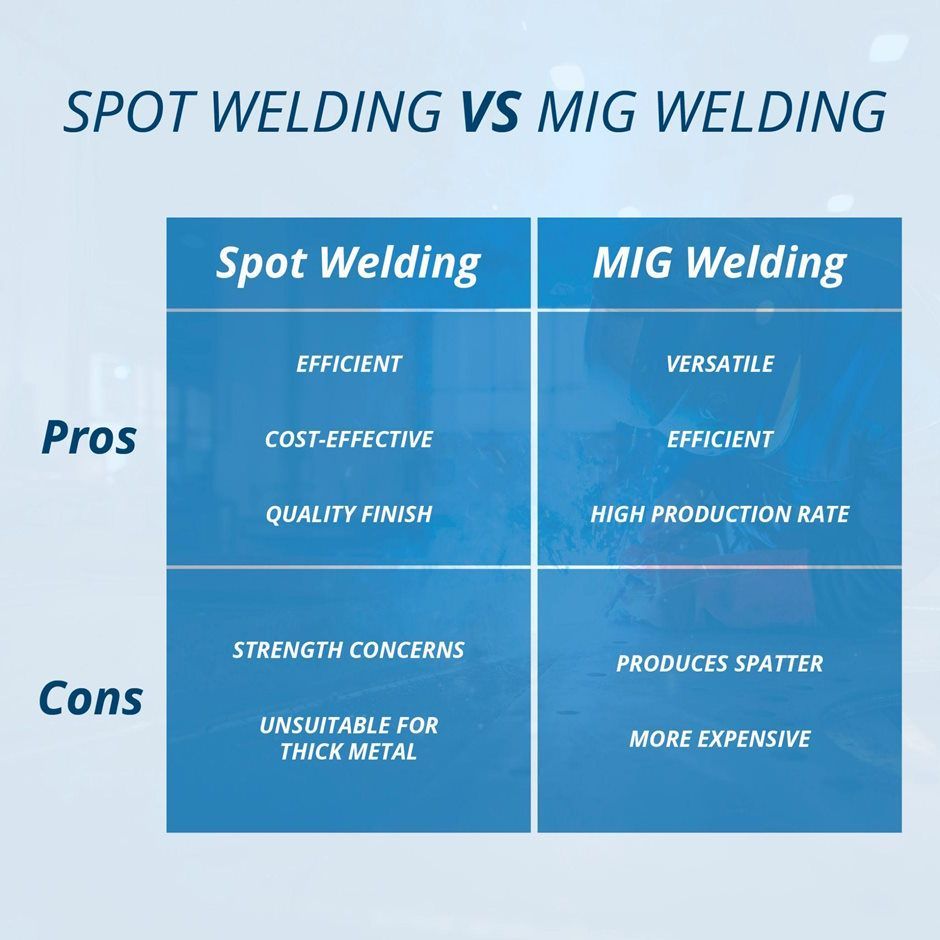

While both welding techniques are widely used, their suitability depends largely on the application. MIG welding offers greater joint strength and deeper penetration, making it ideal for thicker materials and load-bearing metal assemblies. It also provides flexibility when welding different metals, varying thicknesses or components requiring continuous seams.

Spot welding, by contrast, is best suited to thin sheet metals and applications where speed, automation and cost efficiency are key priorities. Because spot welds are localised, they do not offer the same structural strength as MIG welds, which limits their use in heavier-duty applications.

From a cost perspective, spot welding typically requires fewer consumables, as there is no need for filler wire or shielding gas. MIG welding equipment and consumables can be more expensive, but the process often delivers stronger, more versatile results, particularly for complex fabrication projects.

Choosing the Right Welding Method for Metal Assemblies

Selecting the most appropriate welding technique depends on factors such as material thickness, required joint strength, production volume and budget. In many manufacturing environments, MIG welding and spot welding are used alongside one another, each fulfilling a specific role within the fabrication and assembly process.

For businesses producing complex metal assemblies, having access to both welding methods provides flexibility and ensures the most efficient approach can be applied to each component.

Specialist Welding and Fabrication Services

Cotmor Tool & Presswork offers specialist MIG welding and spot welding services as part of our comprehensive metal fabrication and assembly capabilities. With decades of experience and a fully equipped facility in the West Midlands, the team supports a wide range of industries with high-quality, precision-engineered solutions.

By delivering in-house welding, fabrication and metal assemblies, Cotmor Tool & Presswork helps clients reduce lead times, control costs and maintain consistent quality standards throughout production. To discuss your project requirements or request a quote, get in touch with our team today.